PowderMaster PM-8000 Series

Heavy-Duty Auger Filling System for 20-50kg Powder Packaging

40 Bags/Hr ? ±0.1% Accuracy ? ATEX Zone 22 ? Zero Cross-Contamination ? 10-1,000,000 cP

Technical Specifications

| Parameter | PM-8100 (Standard) | PM-8200X (ATEX) | PM-8300H (High-Visc) |

|---|

| Capacity | 20-50kg (±0.1%) | 20-50kg (±0.15%) | 20-50kg (±0.12%) |

| Throughput | 40 Bags/Hour | 36 Bags/Hour | 32 Bags/Hour |

| Accuracy | ±0.1% Gravimetric | ±0.15% | ±0.12% |

| Viscosity Range | 10-500,000 cP | 50-300,000 cP | 50,000-1,000,000 cP |

| Material Compatibility | Flour ? Cement ? TiO? ? Milk Powder ? Polymers | Same + Explosive Powders | Same + Nano-Powders |

| Filling Technology | Twin-Screw Auger + Load Cells | ATEX Gear Auger | Heated Shear-Thinning Auger |

| Material Contact | 316L EP (Ra<0.4μm) | Hastelloy C276 | Ceramic-Coated Path |

| Dust Control | -30Pa Hood + HEPA Filtration | Explosion-Proof Filter | CIP/SIP Ready Enclosure |

| Residual Control | <0.5g (Teflon Scraper + Vacuum) | <0.3g | <0.1g |

| Changeover Time | <5 min (Tool-Free) | <6 min | <4 min |

| Power | 380V/50Hz, 11kW | 24VDC Ex ia | 380V/50Hz, 15kW |

| Certifications | CE, ISO 9001 | ATEX Zone 22 | FDA 21 CFR 210/211 |

Core Innovations

1. ZeroLoss? Precision Auger

Performance Metrics:

| Powder Type | Bulk Density | Flow Rate | Accuracy |

|---|

| Titanium Dioxide | 0.8g/cm3 | 25kg/min | ±0.08% |

| Wheat Flour | 0.5g/cm3 | 18kg/min | ±0.12% |

| Polypropylene | 0.4g/cm3 | 12kg/min | ±0.15% |

2. ExploShield? ATEX Protection

| Technology | Function | Certification |

|---|

| Nitrogen Inerting | O?<8% in Hopper | ATEX 2014/34/EU Zone 22 |

| Spark Detection | IR Sensors + CO? Flood | SIL-2 |

| Static Dissipation | Ionized Air Curtain (10? ions/cm3) | EN 60079-32-1 |

Industry-Specific Engineering

Food & Pharma

| Feature | Technology | Certification |

|---|

| Cross-Contamination | Quick-Change Auger Cartridges | USDA Organic |

| Hygienic Design | EHEDG EL Class I Path | 3-A Sanitary Standard |

| Moisture Control | Dehumidified Air Flushing | HACCP Compliance |

Chemicals & Minerals

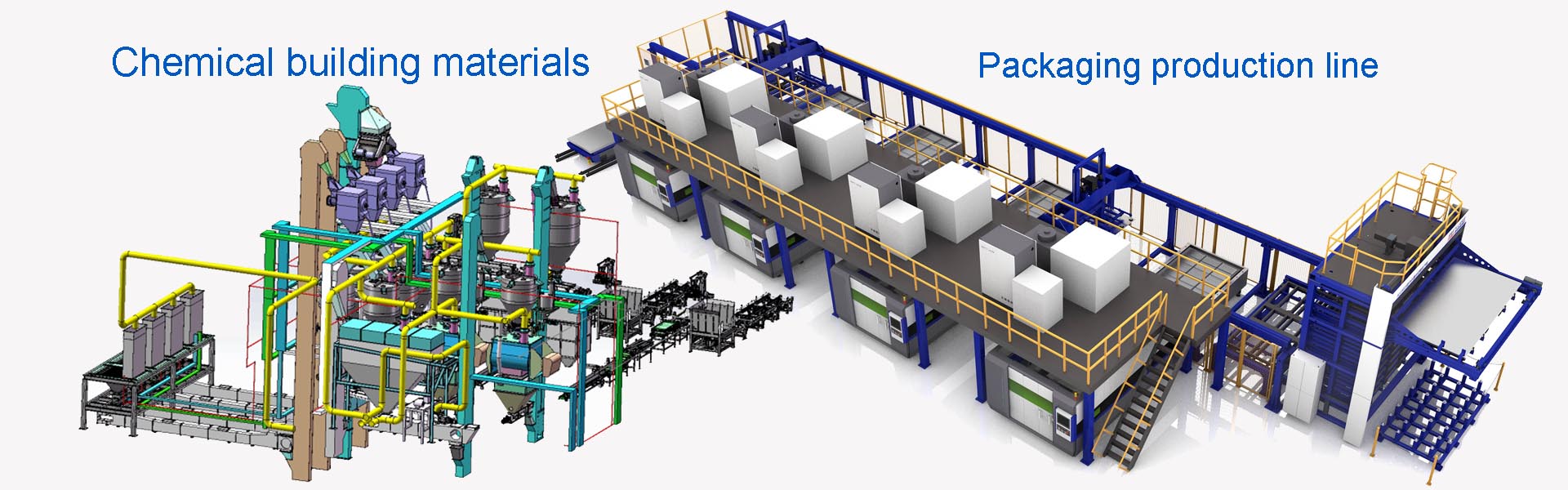

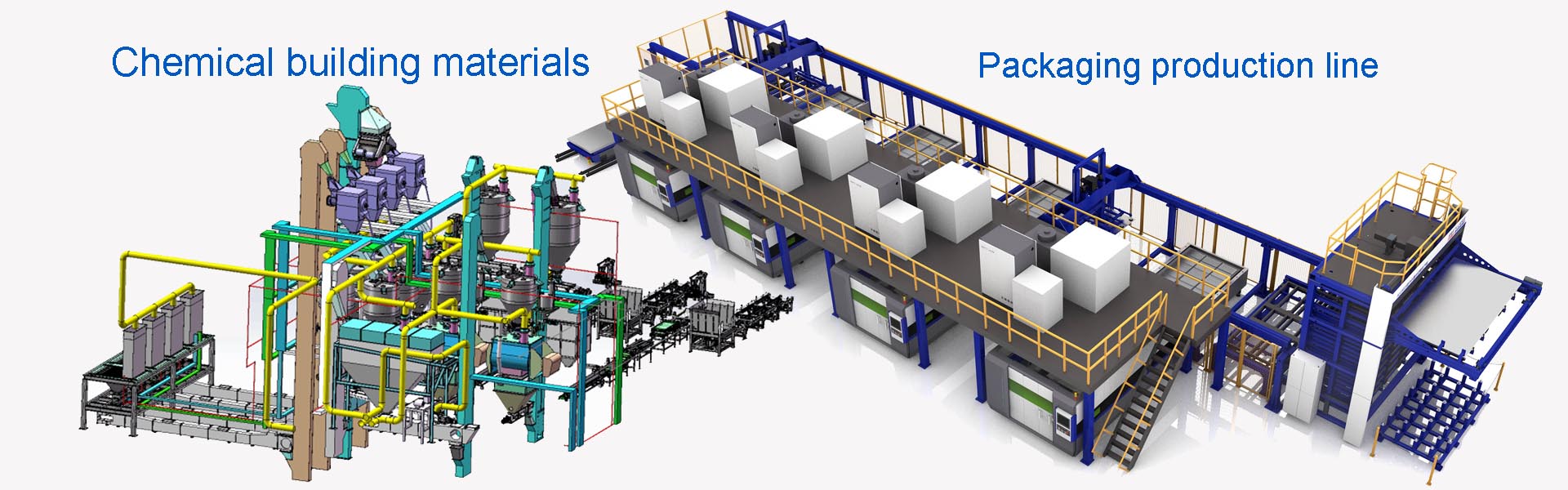

Construction Materials

| Challenge | Solution |

|---|

| Abrasion Wear | Tungsten Carbide Auger (2,200 Hv) |

| Segregation | Pulsed Vibration Agitator |

| Caking | Fluidized Bed + Anti-Bridging Rods |

Smart Control System

**10" HMI with PowderOS?**

AI-Driven Features:

Predictive Maintenance:

| Component | Alert Threshold |

|---|

| Auger Wear | Torque >120% Baseline |

| Bearing Failure | Vibration >4.5mm/s |

Quality Guardian:

| Parameter | Precision |

|---|

| Moisture Content | ±0.1% (NIR Sensor) |

| Particle Size | Laser Diffraction (0.1-1000μm) |

Technical Advantages

Powder Packaging Precision:

? Gravimetric Mastery:

| **Technology**| **Performance**|

|-------------------------|------------------------|

| Twin-Screw Auger| 25kg/min Flow Rate |

| Air Buoyancy Compensation | ±0.05% Accuracy |

| Real-Time Density Adjustment | 0.1g/cm3 Resolution |

? Explosion Safety:

1. Zone 22 Pressurized Cabin

2. 0.01s Spark Detection Response

3. Conductive Path (<10? Ω)

? Cleanability Excellence:

- Tool-Free Auger Removal

- CIP 15-min Cycle (ATP<5 RLU)

- Material-Specific Cartridges

Certifications

? ATEX 2014/34/EU Zone 22 (PM-8200X)

? FDA 21 CFR 210/211

? EHEDG EL Class I

? ISO 9001:2015

Case Study

BASF Ludwigshafen Plant:

“After deploying PM-8200X for titanium dioxide:

Output: 22 → 40 Bags/Hour (+82%)

Material Savings: 3.2% → 0.15% ($420,000/year)

Dust Explosion Incidents: 4 → 0

ROI: 5.8 months”

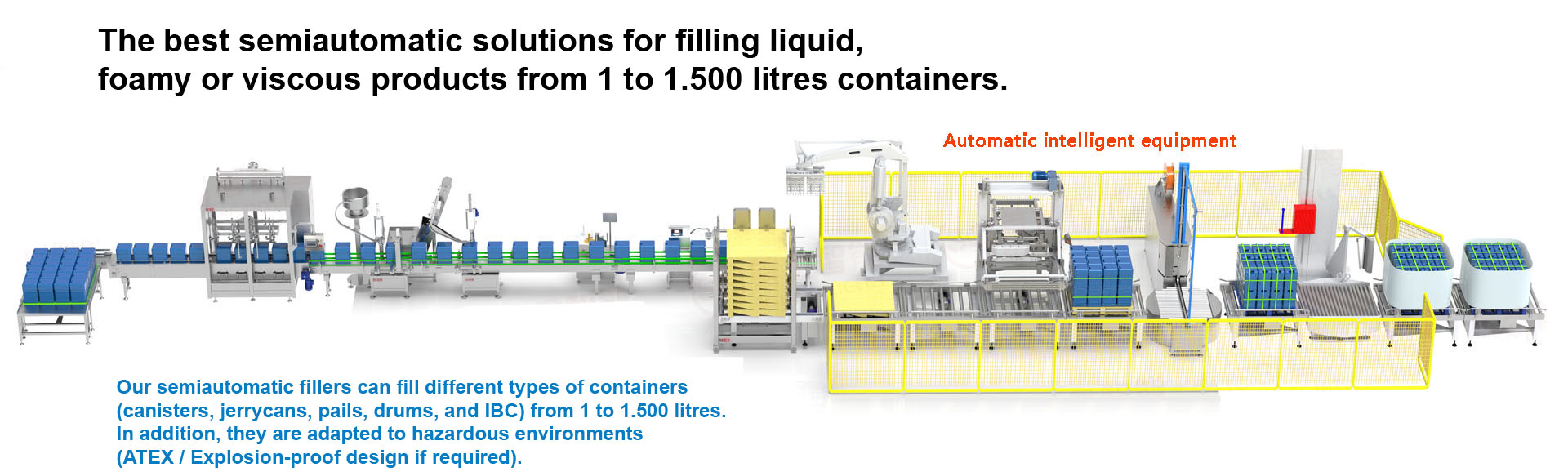

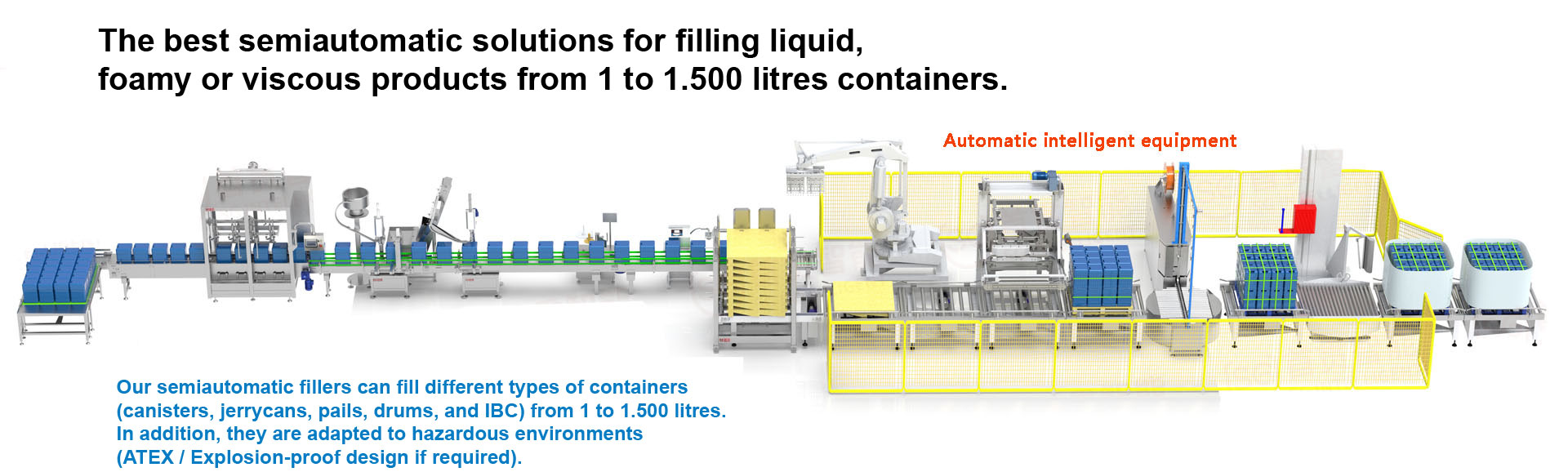

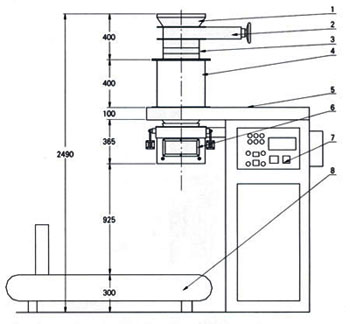

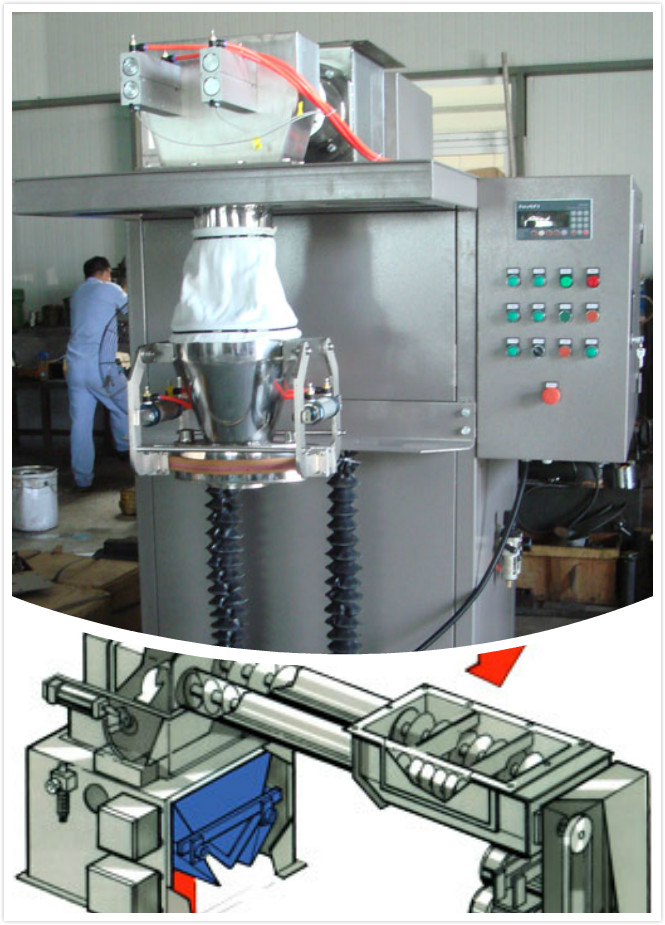

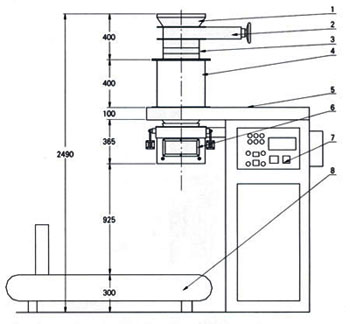

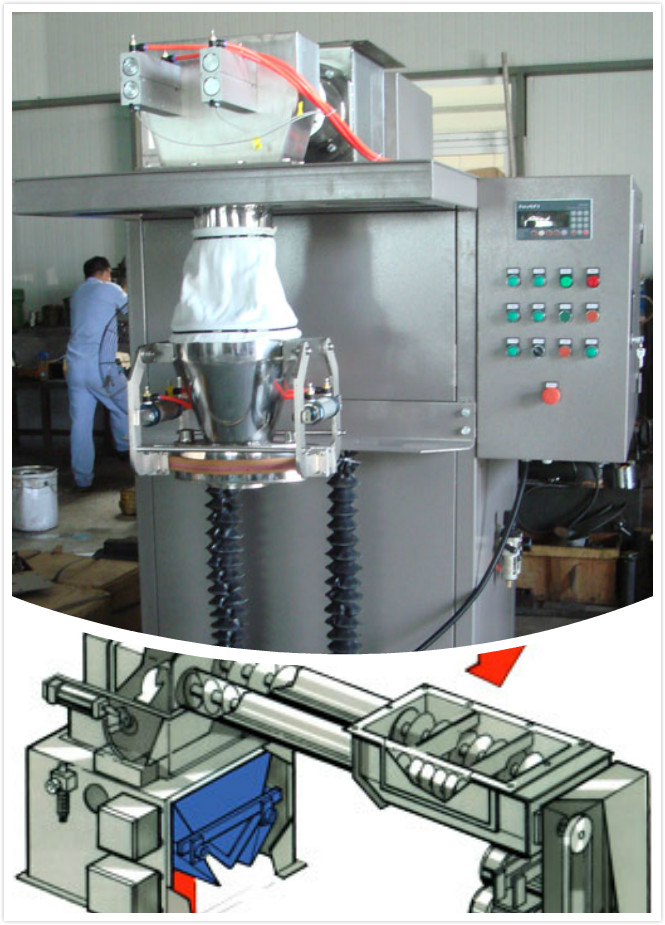

Picture of powder auger packaging machine:

CONTACT US

Skype: fayfaywang1027

QQ: 429682794

Whatsapp: 008618016442021

E-mail: glzoncn@163.com

https://glzon.en.alibaba.com/

cel: +0086 18016442021