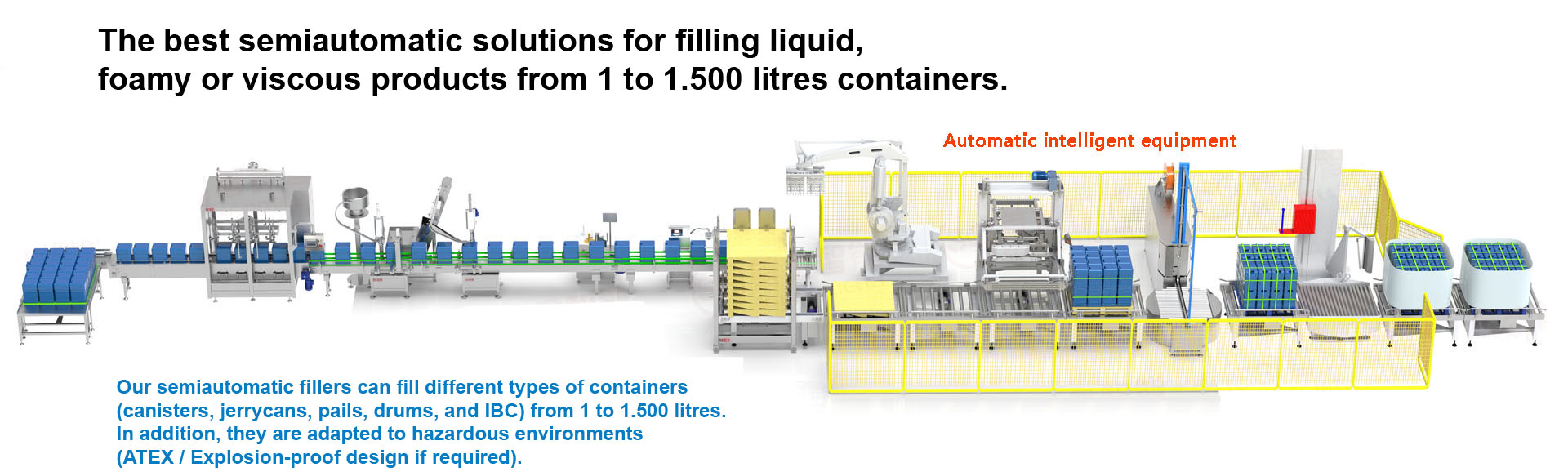

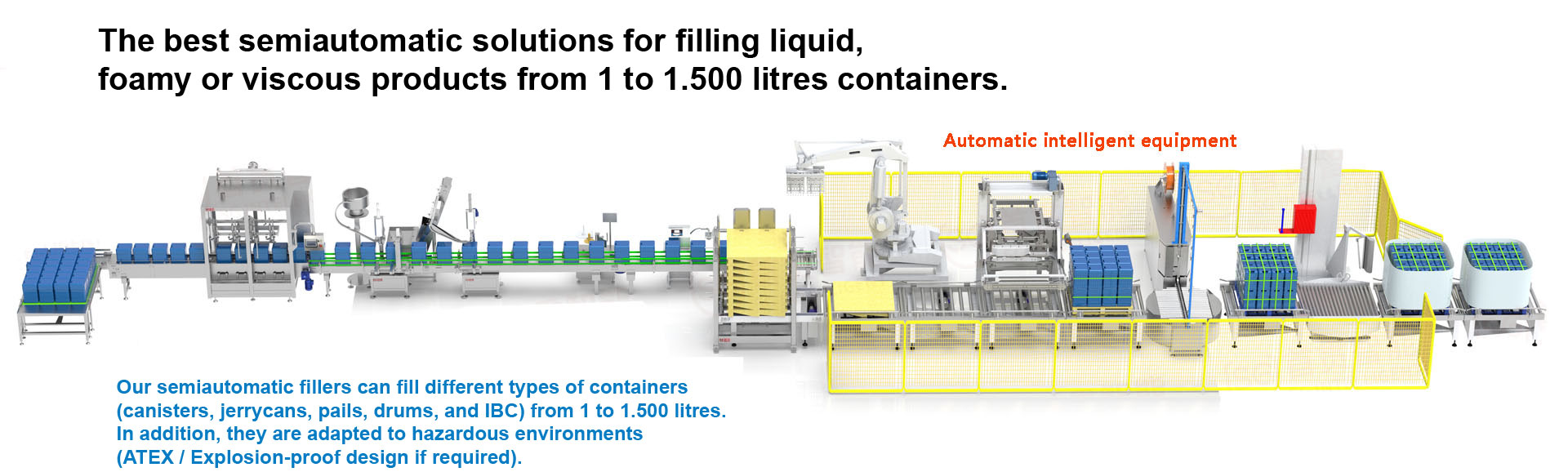

Product Introduction: Semi-Auto Ex-Proof Drum Filler

Engineered for Hazardous Zones

The Guangzhi Ex-DrumFill DSF-1000EX is an ATEX/IECEx-certified semi-automatic drum filler designed for flammable liquids, solvents, and volatile chemicals. Combining explosion-proof components with precision filling (±0.3% accuracy), it ensures safe, efficient operations in Zone 1/21 environments. Operators control drum positioning via footswitch while the system handles filling, weight monitoring, and emergency shutdowns.

Explosion-Proof Safety Features

| Component | Certification | Protection Mechanism |

|---|

| Control Cabinet | ATEX II 2G Ex db IIC T6 Gb | Flameproof enclosure (IP66) |

| Filling Nozzle | IECEx Ex de IIC T6 | Static-dissipative PTFE + grounding |

| Load Cells | ATEX II 1G Ex ia IIC T4 Ga | Intrinsic safety barrier |

| HMI Panel | Non-incendive (Ex nA) | Touchscreen with capacitive lock |

| Emergency Stop | Dual-channel Ex db | Mechanical/PLC redundancy |

Technical Specifications

| Parameter | Specification |

|---|

| Filling Range | 20–220 L (adjustable) |

| Accuracy | ±0.3% (Coriolis mass flow) |

| Max Viscosity | 20,000 cP (high-visc kit: 100,000 cP) |

| Material Contact | 316L SS + EPDM/PTFE (anti-static) |

| Power Supply | 230V/50Hz, 2.2 kW (Ex-rated transformer) |

| Air Supply | 0.6 MPa, oil/dry air |

| Protection Class | IP66 (indoor/outdoor) |

| Compliance | ATEX 2014/34/EU, IECEx, NEC 500 |

Included Safety Systems

Vapor Containment Hood: Sealed with nitrogen inerting ports.

Auto Grounding Clamps: <10 Ω resistance verification.

Overfill Prevention: Dual-sensor (weight + ultrasonic).

Emergency Ventilation: 300 m3/hr exhaust backup.

Gas Detection Interface: Syncs with site VOC monitors.

Target Applications

Chemical Solvents: Acetone, toluene, ethanol.

Paints & Coatings: Resins, thinners, additives.

Pharma Intermediates: Isopropanol, ethyl acetate.

Fuel Additives: Octane boosters, injector cleaners.